Francois Savoye, Vice President E-mobility Solution Offer

Interview

Interview with Renault Trucks about our twelve new e-trucks

13 December 2022

Since summer 2022, twelve Renault Trucks e-trucks have been on the road at Planzer. They are mainly used in city logistics. In an interview with our competence partner Renault Trucks, we find out how fast the electrification of motor vehicles is progressing and what opportunities and risks are associated with it.

Francois Savoye, Vice President E-mobility Solution Offer

// Planzer: How much CO2 do you save with an electric truck compared to a new-generation diesel truck?

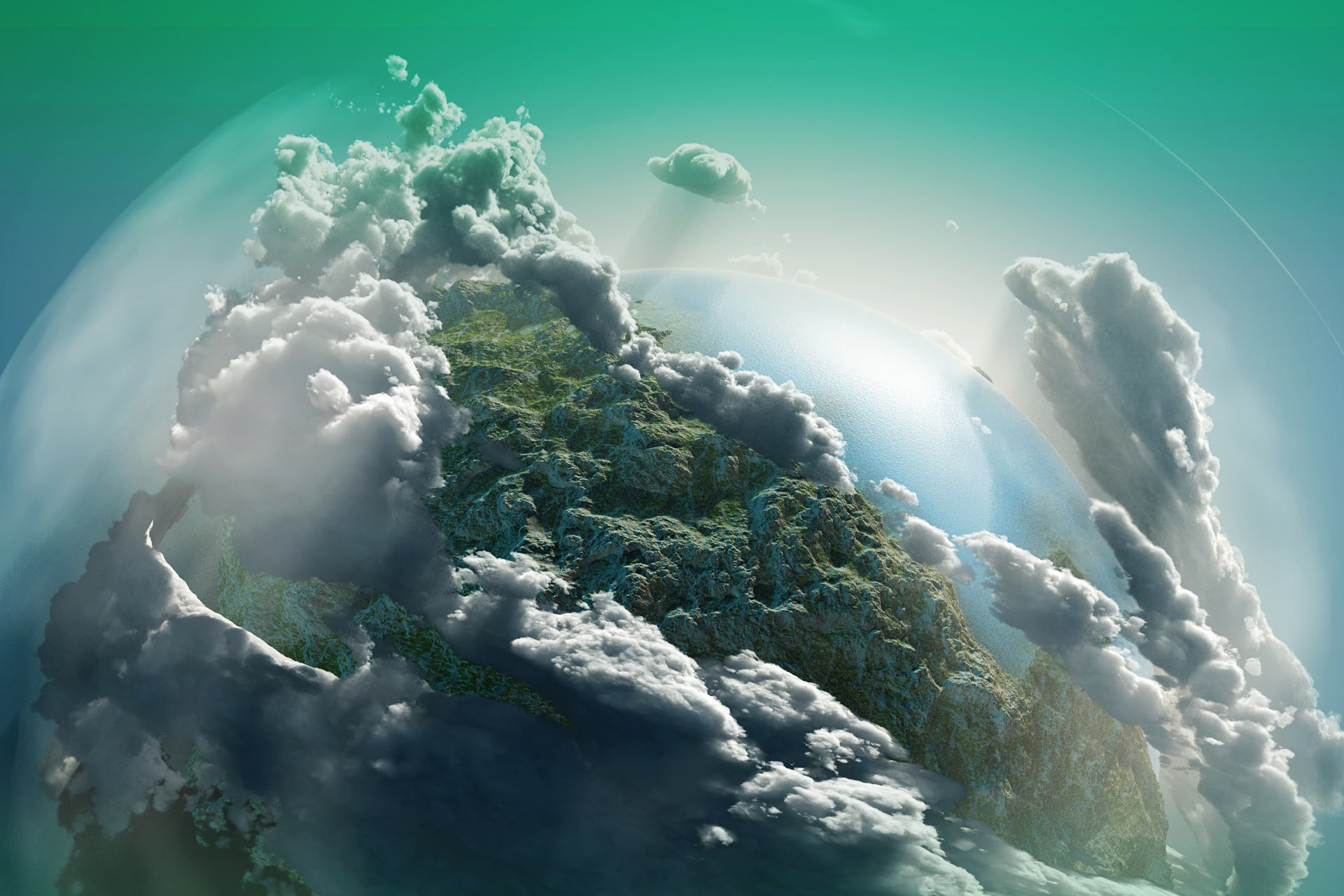

Francois Savoye: Swiss electricity is one of the best and least carbonated types of electricity in Europe. It can reduce the average well-to-wheel emissions generated by a 16-tonne distribution truck by over 80%. In 2022, a 16-tonne electric truck emits 132 g CO2/km. For comparison purposes, a 16-tonne truck run-ning on diesel fuel (including 5% biofuel) emits 837 g CO2/km. In other words, you avoid a good 700 g CO2 per kilometre driven with an electric truck.

- // Why should the costs of maintaining an electric truck be cheaper than the costs of maintaining a diesel truck?Electric trucks have fewer moving parts than conventional diesel ones. If there are fewer moving parts, then there is less wear and tear – a benefit that is reinforced by a smaller amount of fluids. So electric truck maintenance is cheaper than diesel truck maintenance.

- // What new battery technologies can we expect?Batteries have undergone a considerable evolution – and this development will only continue in the future. They offer higher energy density, longer life, greater sustainability and lower costs. In addition to the well-known chemicals such as NMC, NCA or LFP that are already used in batteries, alternative technologies such as lithium-air or lithium-sulphur battery chemistry are currently being tested in laboratories. Combinations like these harbour promising potential for our applications. You might remember that the first lithium-ion batteries were developed in 1990. So it will still be a good while yet until the new technologies for automotive applications are considered mature.

- // Which types of drive could catch on as alternatives to the battery-electric drive?At Renault Trucks, we are counting on the energy mix. Different technologies therefore continue to coexist on the market. Even though our industry is dominated by electric technologies such as battery-electric and hydrogen-powered solutions, there will always be a small proportion of internal combustion engines that run on either renewable fuels or hydrogen – especially for challenging applications or specialist segments. But we believe that battery-electric vehicles will make up the majority. At present, they offer the most efficient path to decarbonisation at a reasonable cost.

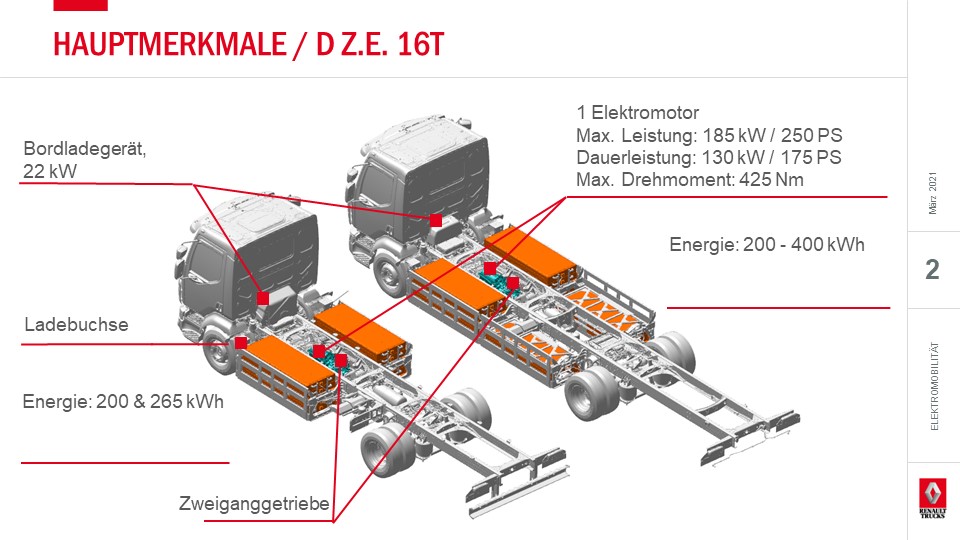

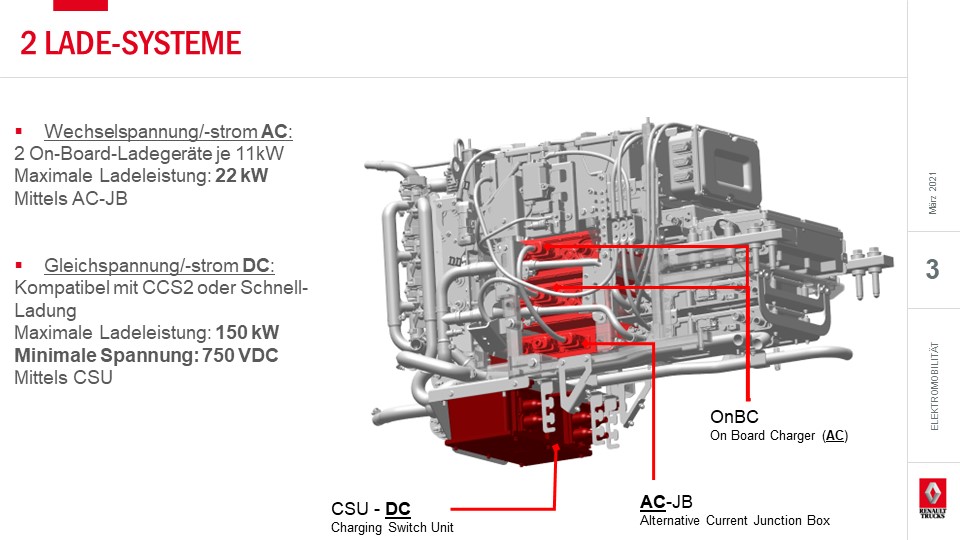

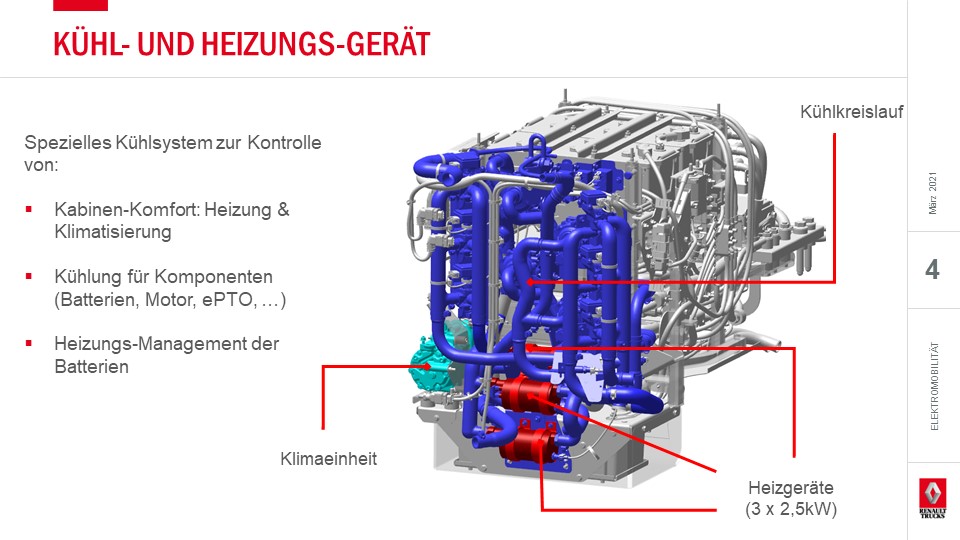

(Graphics only available in German)

(Graphics only available in German) - // How will the ranges per battery charge develop?They will continue to increase over time, supported by batteries’ growing energy density. The public charging network is continually evolving and becoming more powerful. It will support truck operators by providing the flexibility they need in their daily operations. The range race is problematic in our view, because the best range isn’t necessarily the largest, but rather the one that best suits truck operators’ needs. Having more batteries than are needed for use affects the vehicle’s mass and thus its efficiency and productivity – not to mention the fact that it ties up capital without adding any value. By 2025, most OEMs will offer electric traction engines with a 500 km range that can be extended to 1,000 km thanks to a 45-minute 750 kW fast-charging process during the lunch break.

- // What is the ‘life expectancy’ of an electric truck in terms of mileage, age and critical components?A battery’s lifetime is closely correlated to its application. Batteries have a lifespan of between six and ten years on average, depending on the area of use. At Renault Trucks, we offer service contracts that protect truck operators against failure for up to a decade.

- // How sustainable is the manufacturing process for modern energy systems like the lithium-ion battery?Every technology has its challenges. For the battery industry, the challenge is raw materials supply/production. We are deeply committed to minimising the impact of mineral extraction and processing. Firstly, we repeatedly conduct due diligence checks to verify the environmental and social impacts of mining the likes of cobalt. Secondly, we work in international task forces to create mining labels that will form part of the future battery passport. And, thirdly, we integrate minerals from open-cast mining into our batteries.

- // How safe are the lithium-ion energy systems if an accident occurs or a fire breaks out?Safe. The safety risks are firstly reduced by the design and secondly verified by testing. Among other things, the design consists of control units that monitor voltages and temperatures so they can shut down part of the battery if it turns out a cell is defective. Additionally, strong battery holders prevent collapse. The verification tests follow the ECE R100.01 legal code, including fire, crash, short circuit and many other tests.

(Graphics only available in German)

(Graphics only available in German) - // What challenges do transport companies have to overcome?Quite a few. Firstly, from a financial point of view, alternative drives harbour new risks and other investment implications. From an operational perspective, new technologies translate into a new way of operating the vehicles. From a human and cultural standpoint, this change requires new skills – not to mention the fact that the introduction of the latest technology challenges the structure of traditional business models.

- // What do you think should be the percentage of electric trucks to diesel trucks in a fleet?That question isn’t one that can be given a general answer. However, it is clear that in a country like Switzerland – where electricity produces the lowest CO2 emissions in Europe – converting a major part of the fleet to electric trucks over the coming years is a sensible move given how fossil-fuelled vehicles are being taxed at present.

- // What electric truck price trends can we expect to see in the future?Electric vehicles are likely to come down in price, which in turn will gradually cut the cost of decarbonisation. The current inflationary environment and general tensions in the supply chain are naturally causing people to ask questions about the extent of this price drop. But it is clear that economies of scale are allowing manufacturers to offer their electric vehicles at ever lower prices.

- // How do you go about recycling your batteries?The Volvo Group has created a new business area called ‘Volvo Energy’, which is playing a key role in introducing the circular economy for batteries. After its first use in the vehicle, the battery is reconditioned in our factories or recycled entirely so it can be used in another vehicle. When the modules’ energy density becomes too low, they are used in stationary applications for grid management purposes. And when the cells finally die, they are recycled at least 70% for lithium and 94% for nickel, cobalt and copper. That way, we are complying with the future European regulatory framework for batteries, which, however, has not been fully implemented yet.

(Graphics only available in German)

(Graphics only available in German) - // What does the second-hand market for electric trucks look like, and how will it develop?There is still no second-hand market for electric trucks. Given the equipment’s long life, the increasing importance of the circular economy at the core of our business model, and the fact that batteries have attractive value retention potential, we at Renault Trucks are playing an active role in establishing this market.

- // What do you think of exchangeable batteries (i.e. replacing batteries instead of quickly charging them)?Battery swapping is very popular in China for electric construction vehicles. At Renault Trucks, we are currently examining the possibilities for long-distance trucks. What makes battery swapping advantageous is the fact that the energy can be recharged in five to ten minutes and that the battery swapping station charges the battery when electricity is cheapest. However, this requires substantial investments to be made in battery swapping stations and additional batteries. And it increases battery ageing slightly. We assume that the costs per kilometre will be higher than they are for fast-charging stations. We’ll know more in a few months.

Thank you, Francois Savoye, for the interesting interview.